Building Better Supply Chains for Domestic Manufacturing Independence

Patriot Medical Devices

1/10/2023

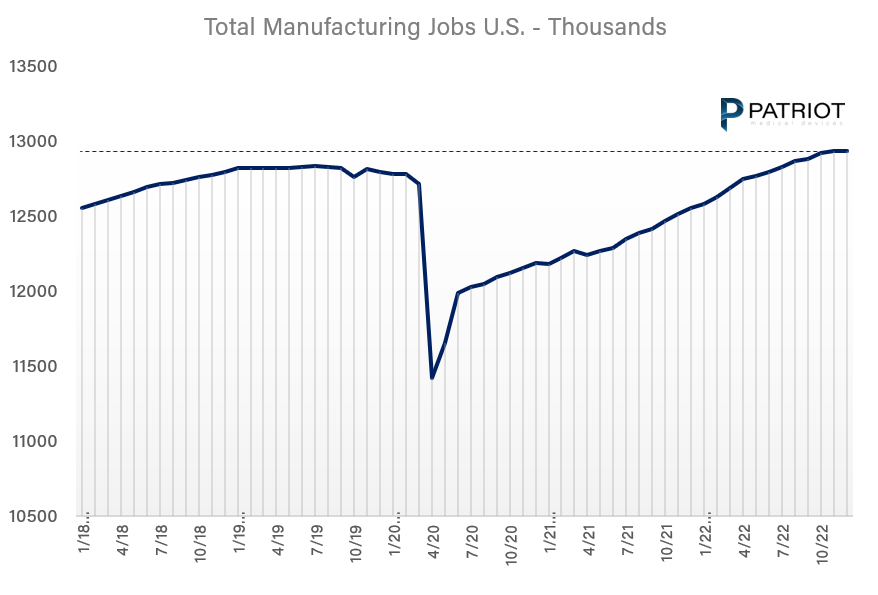

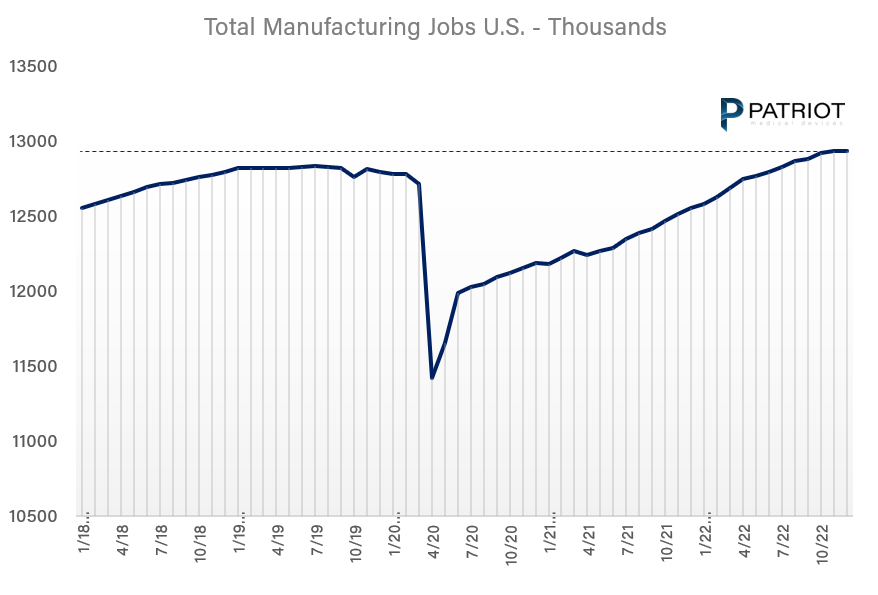

Manufacturing jobs in the United States have reached their highest number of employees in the last twelve years, according to the Bureau of Labor Statistics.1 This clearly indicates that U.S. manufacturing supply chains are beginning to rebuild its manufacturing reach. The U.S. is slowly but surely loosening foreign manufacturers’ grip on the products consumers have access to buying.

Since the 1990s, many companies have been shifting their sourcing and production globally and adopting lean manufacturing methods to reduce costs. This globalization has led to a significant increase in global trade, which rose from 39% to 58% of global GDP between 1990 and 2019. However, this globalization also exposed companies to a variety of supply chain risks, including natural disasters, labor disputes, cyberattacks, and supplier disruptions.

As a result, globalization has slowed down, a phenomenon known as “slowbalisation,” and global trade as a percentage of GDP has decreased from 61% to 58% between 2008 and today.2 The COVID-19 pandemic and the accompanying economic crisis have only exacerbated these trends and exposed further supply chain vulnerabilities.

COVID’s Disruption of Supply Chains

COVID-19 is not the first epidemic to disrupt supply chains, but it has had a much greater impact on global trade and domestic supply chains than previous epidemics such as SARS, swine flu, Ebola, and avian flu. The ongoing pandemic has revealed weaknesses in global supply chains, including over-reliance on China for essential medical goods and equipment and an inability to rapidly shift production and logistics in response to changing customer demand. These issues have highlighted the fragility of modern supply chains and the need to improve resilience and agility in their design. Both companies and governments are now recognizing that efficiency cannot be the sole focus when designing supply chains, and that a new approach to competitive resilience is necessary to create supply chains that can withstand future disruptions.

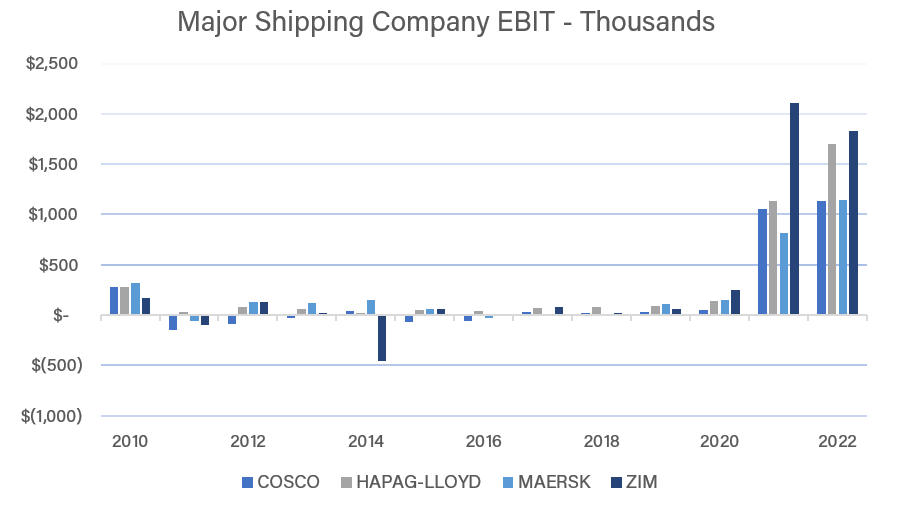

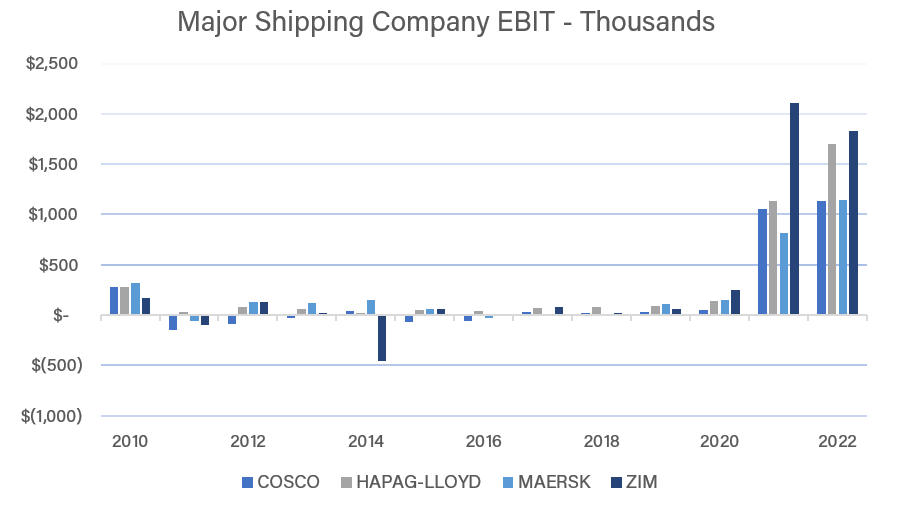

Below is a chart representing the increase in profits taken by the major shipping companies in the world.3 Shipping from foreign countries to the United States saw shipping prices increase as much as 5 times the regular rate.

How to Create Resilient Supply Chains

To improve supply chain resilience, it is important to have rapid detection, response, and recovery mechanisms in place, as well as end-to-end data-driven supply chain control, redundancies such as emergency stockpiles and diversified sourcing, collaboration between private and public supply chain stakeholders, and effective demand planning processes. Domestic supply chains are important because they allow for quicker response times to disruptions, reduce reliance on global trade, and can be more resilient to external risks such as natural disasters or pandemics.

Leading multinationals have long recognized the importance of managing supply chain risks and have implemented strategies such as diversifying their sourcing, establishing emergency stockpiles, and collaborating with government agencies to prepare for disruptions. Helping bridge the gap in supply chains is small domestic manufacturers, many who started up during the pandemic to help alleviate supply chain shortages. Partnering with these local small businesses can provide advantages over reliance on large corporate entities. Quicker delivery times, greater flexibility, creation of American manufacturing jobs, reduced reliance on oversees supply chains, lower carbon footprint, and friendly customer service are advantages of going with small American manufacturers to build a more resilient supply chain.

How Patriot is Helping

Patriot Medical Devices is taking action to rebuild America’s medical supply chain by creating a secure, American first supply chain. Our company recognizes the importance of domestic supply chains in providing quicker response times to disruptions, reducing reliance on global trade, and increasing resilience to external risks such as natural disasters or pandemics. By prioritizing American suppliers and manufacturing, Patriot Medical Devices is working to create a more reliable and stable supply chain for critical medical goods and equipment. Additionally, the company’s focus on security helps to protect against potential supply chain disruptions caused by cyberattacks or other threats. Overall, Patriot Medical Devices is playing a key role in improving the resilience of America’s medical supply chain and ensuring that the country is better prepared for future disruptions.